The right choice for every area of application

Lahnau Akustik offers the right solutions for practically every area of application.

With our acoustic panels made from recycled glass we provide you the option to create the best-possible acoustics in combination with a high-quality design, even in demanding areas such as sports halls.

Children and adults alike feel safe and at ease thanks to high levels of light reflectance, good acoustics and the right fire protection offered by our acoustic systems.

The advantages of these systems are obvious:

- It is easily possible to integrate practically all panel mounted devices in the system

- They can be installed independent of lights, sports equipment and radiant ceiling heaters

- Easy to remove

- Ball impact proof ceilings and wall cladding with a uniform appearance

- Complete system on demand

- We are happy to offer individual consultation

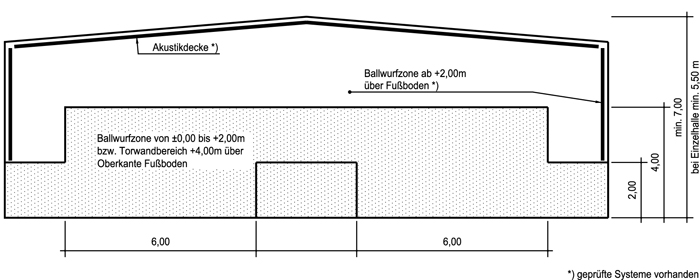

Ball impact resistance:

Building elements are considered ball impact resistant when they are able to withstand mechanical ball impact stress loads without significant changes occurring to the elements and their substructure.

Unlimited ball impact resistance:

The wall area from 0-2.00 m above the floor must always be formed to offer unlimited ball impact resistance. Even impacts by hockey balls are only allowed to result in slight damage to the surface.

Limited ball impact resistance:

All elements installed in the wall area (beginning 2.00 m above the upper edge of the finished floor), which can only be damaged by impacts from hockey balls, are considered limited ball impact resistant. A limited ball impact resistance also suffices for suspended ceilings. Ball impact proof is never spoken of, but rather ball impact resistance.

Test specifications:

DIN 18032, Part 3 Testing ball impact resistance. The requirements placed on ball impact resistance in DIN 18032 always apply to the whole construction, in other words the finishing elements (e. g., panels) and substructure. Considered on its own, there is no such thing as a ball impact resistant panel. Even when DIN 18032 is stipulated, the specifications contained therein fundamentally apply to a clear ceiling height of 5.50 m. The ball impact tests are carried out on ceilings at this height; consequently, they cannot be applied to lower ceilings. The ceiling must be ball impact resistant; in other words, the surface characteristics and the substructure must be durable and not exhibit significant changes in the face of all mechanical stress loads resulting from impacts by handballs and footballs.

Mikropor G bs for ball impact resistant ceilings

Product description:

Acoustic panel consisting of expanded glass granulate with inorganic binder, approx. 18 mm thick, building material class A2 (non-combustible) /// Mikropor G A2 • DIN 4102-A2 • Z-56.426-882 • Inspection mark Test Institute Hoch\ \\\ in the panel core with galvanized wire fabric reinforcement, surface coated with acoustic fleece and painted white with WAF-S (special colours also possible). Edges not coated / no grooves Length in mm: 2500, 1250 Width in mm: 625

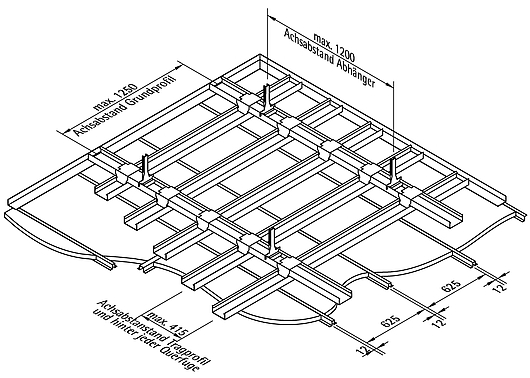

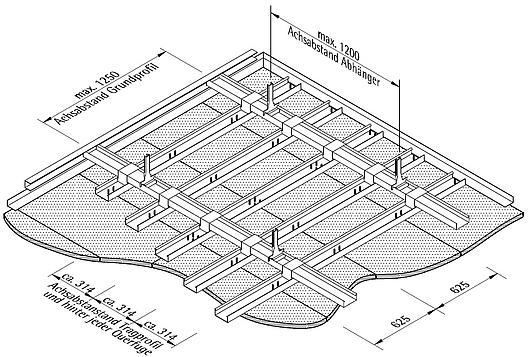

Installation overview:

- The acoustic panels are affixed by means of lapping hat channels LAH 65 with a 12 mm joint width.

- The hat channels are screwed to the support profiles (C ceiling channels) using PAN HEAD self drilling screws 3.5 x 16 mm to DIN 7504.

- The support profiles are joined at right angles to the primary profiles above them with a maximum centre to centre distance of 415 mm using quick-disconnect cross connectors.

- The maximum centre to centre distance of the primary profiles must not exceed 1250 mm.

- The ceiling elements are suspended by means of rigid Nonius hangers or direct hangers.

- The maximum longitudinal centre to centre distance must not exceed 1200 mm.

Mikropor G bs-D for ball impact resistant ceilings

Product description:

Acoustic panel consisting of expanded glass granulate with inorganic binder, no wire fabric reinforcement in the panel core, approx. 18 mm thick, building material class A2 (non-combustible) /// Mikropor G A2 • DIN 4102-A2 • Z-56.426-882 • Inspection mark Test Institute Hoch\\\ surface coated with acoustic fleece and painted white with WAF-S (special colours also possible). Edges – without coating/no grooves Standard formats: Length in mm: 2500, 1875, 1250 Width in mm: 625

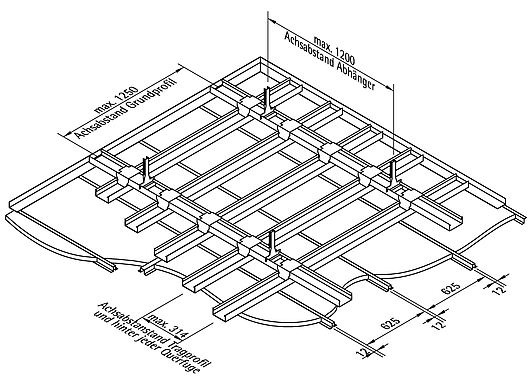

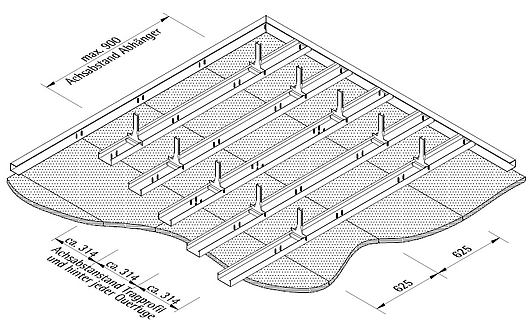

Installation overview:

- The acoustic panels are affixed with a 12 mm joint width by means of overlapping hat channels LAH 65

- The hat channels are screwed to the support profiles (C ceiling channels) using PAN HEAD self drilling screws 3.5 x 16 mm to DIN 7504.

- These support profiles are joined at right angles to the primary profiles above them with a maximum centre to centre distance of 314 mm using quick-disconnect cross connectors.

- The maximum centre to centre distance of the primary profiles must not exceed 1250 mm.

- The ceiling elements are suspended by means of rigid Nonius hangers or direct hangers.

- The maximum longitudinal centre-centre distance must not exceed 1200 mm.

Mikropor G bs-W for ball impact resistant walls

Product description:

Mikropor G bs W acoustic panel - for ball impact proof wall cladding beginning at a height of +2.00 m above the upper edge of the finished floor – beginning at a height of +4.00 m above the upper edge of the finished floor in the area around the goal (please refer to the graphic below in the section General information) consisting of expanded glass granulate with inorganic binder, approx. 18 mm thick, building material class A2 (non-combustible) /// Mikropor G A2 • DIN 4102-A2 • Z-56.426-882 • Inspection mark Test Institute Hoch \\\ in the panel core with galvanized wire fabric reinforcement surface coated with acoustic fleece and painted white with WAF-S. Edges not coated / no grooves Length in mm: 2500, 1250 Width in mm: 625

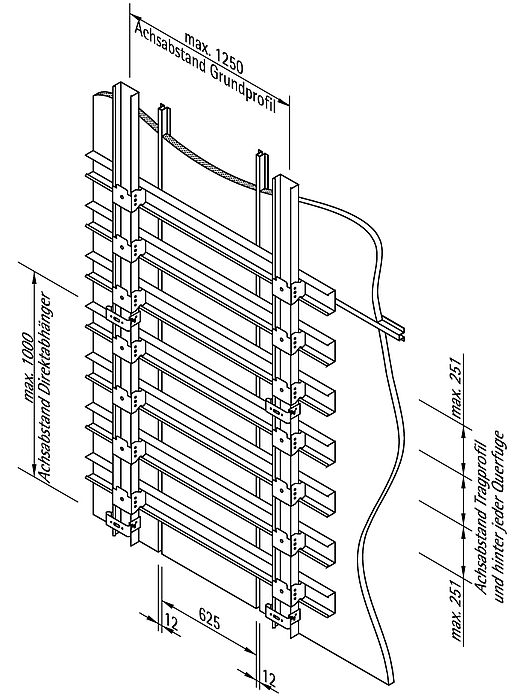

Installation overview:

- The acoustic panels are affixed with a 12 mm joint width by means of overlapping hat channels LAH 65

- The hat channels are screwed to the support profiles (C channels) using PAN HEAD self drilling screws 3.5 x 16 mm to DIN 7504.

- The support profiles are joined at right angles to the primary profiles (C channel) above them with a maximum centre to centre distance of 251 mm using quick-disconnect cross connectors.

- The maximum centre to centre distance of the primary profiles must not exceed 1250 mm.

- The wall cladding is fastened using rigid spacers.

Mikropor G bs-D FWA for seamless ball impact proof ceiling systems

Product description:

The acoustic panels are screwed to the support profiles (C ceiling channels) from the visible side through the panel using phosphate coated, drywall needle point screws, form TN to DIN 18182. The longitudinal centre to centre distance between the screws is 250 mm and 208 mm in a lateral direction. The support profiles are joined at right angles (parallel to the longitudinal edge of the panel) to the primary profiles (C ceiling channels) above them with a maximum centre to centre distance of 208 mm using quick-disconnect cross connectors. The maximum centre to centre distance of the primary profiles must not exceed 1000 mm. The ceiling is suspended by means of rigid Nonius hangers or direct hangers. The maximum longitudinal centre to centre distance must not exceed 1200 mm. Detailed information is available in the Chapter “Seamless acoustic ceilings”.

Products from Lahnau Akustik offer numerous design options. We offer a huge choice of special colours and surfaces. We are happy to offer advice.

Surface:

Acoustic membrane with matt, smooth and non-directional surface, optionally available as sound absorbing (G) or sound reflecting (GT)

Surface colour (visible side):

In special colours as per sample on request; optional antistatic, water-repellent special coating

MIKROPOR® G

Non-directional, fine-pore structured colour coating light reflectance value (white) > 90% (diffuse: 0.9)

MIKROPOR® GT

This version as Mikropor G but sound reflecting.

MIKROPOR® G PATINA

Non-directional, matt, smooth coloured surface coating

(the colour and structure shown in images of surfaces can differ slightly from the original) * Special colour

The 5 steps required to successfully refurbish ball impact resistant acoustic ceilings made from ecologically sound, recycled building materials

- Step 1: Support during on site review of actual condition Step

- 2: Evaluate and assess the actual condition taking into consideration current requirements and DIN standards Step

- 3: Draw up and suggest a system solution and harmonize refurbishment work Step

- 4: Determine costs and draw up planning and tender documents Step

- 5: Carry out refurbishment work

Option 4: Comprehensive refurbishment

After analysing the actual situation the decision is taken that a completely new ceiling system is required. An individual solution is drawn up.

1. Cleaning

- Before cleaning with a damp cloth, carefully remove surface dust with a brush or vacuum cleaner.

- It is possible to remove localized soiling such as fingerprints or trails of soiling close to air outlets using a firm, damp sponge together with a commercially available household cleaner or Moisture-Clean (available as a powder from Lahnau Akustik) in the respective recommended concentrations.

- Then carefully wash down the cleaned surface with clean, clear water and dab dry with an absorbent cloth or paper (kitchen roll).

- We recommended you test clean an inconspicuous area each time before cleaning.

Professional refurbishment must be carried out using Wilhelmi acoustic paint WAF-R 86 (special colours WAF-R 87).

- Quantity used during refurbishment: 400-700 g/m² depending on the degree of soiling

- Ensure the room temperature does not fall below 12 °C when applying the coating; the relative humidity should not exceed 70%.

- Once applied immediately ensure the rooms are ventilated and dehumidified.

2.1 Refurbishment

If the acoustic ceiling has become heavily soiled after many years of normal use and can no longer be cleaned properly, it is possible to restore it to a condition virtually as good as new by applying a refurbishment spray.

When applied professionally in accordance with the manufacturer’s instructions the acoustic absorbency of the wall or ceiling surface is not impaired. The refurbishment can be repeated several times, if required.

Under no circumstances should emulsion paints be applied to the surfaces using a brush or roller, otherwise the sound absorbing properties will be lost.

It is only possible to guarantee the acoustic characteristics will be retained by engaging a professional company that uses the appropriate coating machinery to professionally apply the refurbishment spray, e.g.,

Strobl Beschichtungstechnik GmbH

Hermann-Volz-Straße 50

D-88400 Biberach/Riß

Tel. +49 7351/4400-0

Fax +49 7351/4400-60

Quality management

It is possible to achieve continual improvement with the aid of quality management by involving all members of staff and optimizing company procedures across all departments. Fulfilling customer requirements is central to all we do. An integrated management system for quality, environment and occupational health and safety according to EcoStep.

Environment management

As a manufacturer of environmentally friendly products based on the raw materials glass and metal Lahnau Akustik GmbH is passionately committed to protecting the environment. We wish to contribute towards balancing economy and ecology with the aim of combining sustainable development with the careful use of resources.

The ecological benefits of acoustic panels made of recycled glass:

- 100% recycled glass

- Sustainable

- Conserve natural resources

- Winner of many ecological awards

- Optimize your LEED rating

- Healthy home environment “built-in”

- Reduce CO2

- Optimize heat insulation

With you in mind, we have introduced:

An integrated management system for quality, environment and occupational health and safety. An expert assessment documented in a report verifies that the management system fulfils requirements and, as a consequence, the core stipulations of the following standards:

- ISO 9001:2000

- ISO 14001:2004

ILO guidelines on occupational safety and health (2001)