IMAGIO® G Design / IMAGIO® G A 2 networked

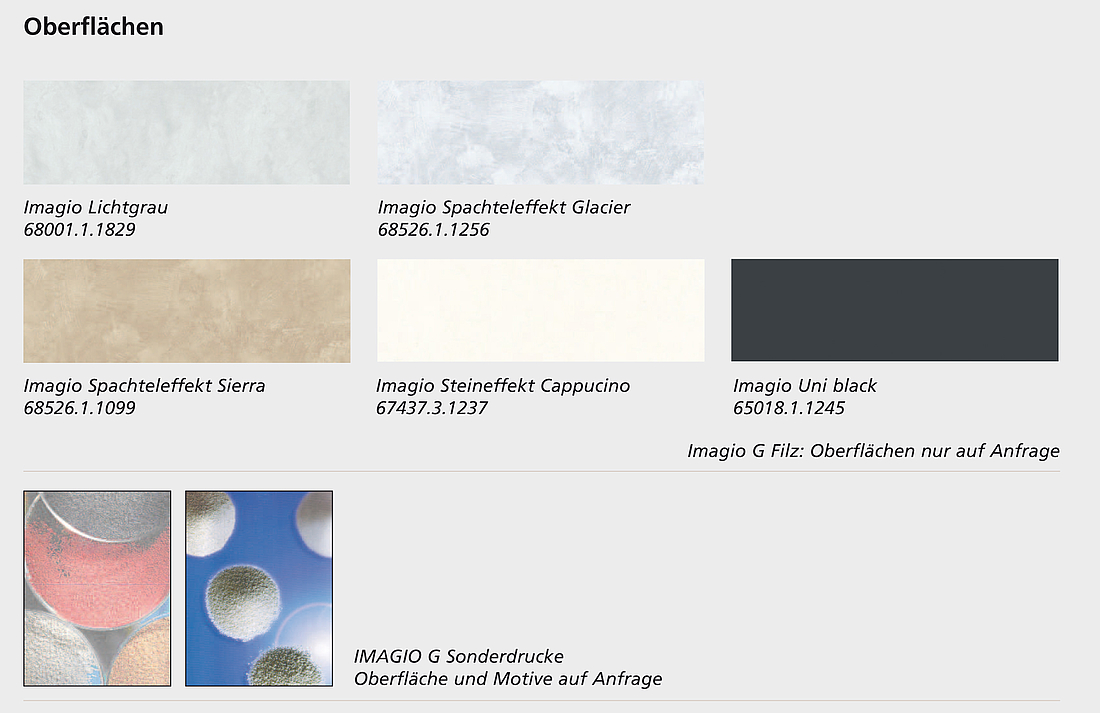

Fleece surfaces in colours and patterns

glass fabric surfaces in special colours

Wilhelmi acoustic panels Imagio® G from Lahnau Akustik GmbH are made from recycled glass granulate and bound with inorganic binder. The surface comprises needle felt surfaces in a variety of colours and patterns. The max. format of the stable, 18 mm thick panel core is 2500 x 1250 mm, which is easily manually processed. The fleece surfaces have a pleasant haptic; thanks to the variety of colours and patterns they offer the perfect solution to optimize the acoustic properties of wall cladding.

Base panel:

Expanded recycled glass granulate, bound with inorganic binder

Surface:

IMAGIO® G DESIGN

Acoustic membrane available in different patterns, colours, structures

IMAGIO® G A2 COMPOSITE

Glass fabric in different colours and structures

IMAGIO® G A2 special prints

Surface and motifs on request

Care / refurbishing:

Vacuum clean with vacuum cleaner and

brushes, clean with carpet cleaner

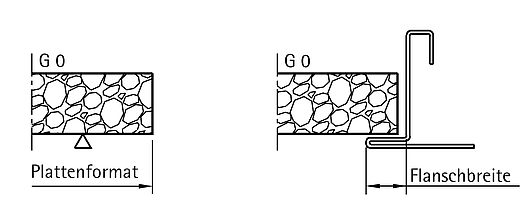

Edge configurations:

IMAGIO® G DESIGN

Grooved and thermoplastic edge

IMAGIO® G A2 COMPOSITE

Edges not coated

IMAGIO® G A2 FILZ

Edges not coated

and non-grooved

Panel thickness:

Approx. 18 mm

Building material class:

base panel A2 (s1, d0) (non- flammable)

Format:

2500 mm x 1250 mm

Weight per unit area:

Approx. 7.5-8.5 kg/m2

Humidity:

Permanent high levels of humidity

(> 70%) affect the

dimensional stability of the panels.

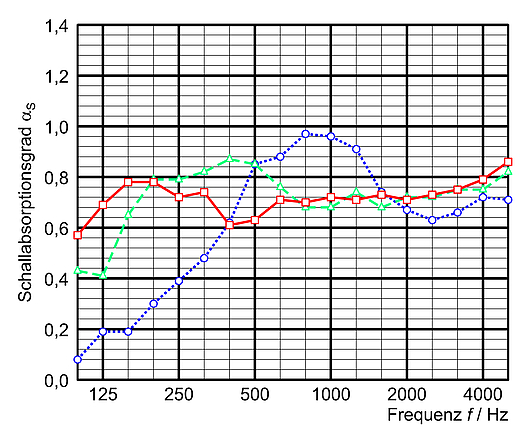

Sound absorption level:

See measuring curve in the chapter

Acoustic test certificates

Surface:

IMAGIO® G DESIGN

Acoustic membrane available in various patterns, colours, structures

IMAGIO® G A2 COMPOSITE

Glass fabric available in different colours and structures

IMAGIO® G A2 Special prints

Surface and motifs on request

(the colour and structure shown in images of surfaces can differ slightly from the original)

We would be more than happy to send you a sample.

Feel free to contact us.

We develop effective acoustic building materials in close cooperation with scientists, clients, architects and contractors. Utilizing these high-quality materials facilitates optimum speech intelligibility in our built-up environment.

At the same time, the design options available with regard to material, surface, colour and shape are so varied that it is possible to efficiently combine the demands placed on man and an eco-friendly architecture with one another on the basis of the latest scientific findings.

A variety of acoustics tests are available to download from the Download archive

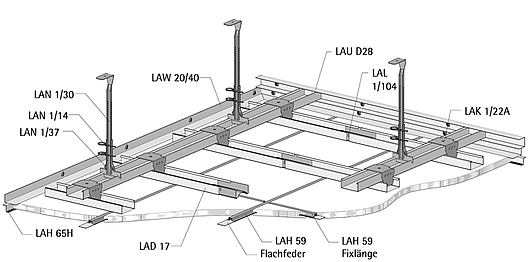

Constructions & details:

Information about the following constructions is available here:

Overview of our standard grooves:

The wide variety of possible constructions makes it necessary to offer a broad portfolio of groove variants.

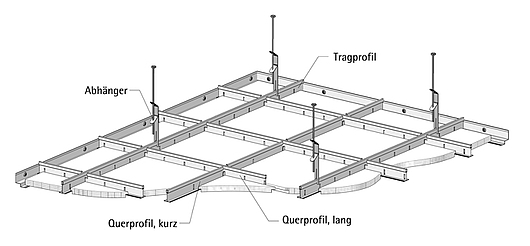

Acoustic panels from Lahnau Akustik GmbH are suitable for both T-profile substructures as well as for numerous substructures developed by us.

The PDF document contains an overview of the available variants.

Different grooves are possible on request.

Installation system with hat channels

- The ceiling system designed to meet the highest requirements vis-à-vis stability; also suitable for large sized acoustic panels

- Panel lengths up to 2500 mm panel widths up to 625 mm; wider panel widths with added reinforcement on request

- Ceiling void remains accessible; all acoustic panels can be removed and reinstalled using tools; no need to push up into the void to remove

Lay-on / lay-in system with visible T-profile

- The ceiling system for a variety of grid dimensions; easy access to ceiling void

- Panel lengths up to 2500 mm, panel widths up to 625 mm with a T-profile width of 15 mm or 24 mm

- Square formats up to 1250 x 1250 mm can be installed without added reinforcement. Possible to remove and reinstall without tools

Cleaning fabric surfaces

Clean adherent soiling (e.g., surface dust) using a vacuum cleaner with brush attachment; do not push against the surface to be vacuum cleaned. It is possible to remove stubborn soiling using commercially available cleaning foam for fabric surfaces. Observe the respective instructions for use. Do not rub the surface.

It is essential to test clean an inconspicuous spot before cleaning.

Quality management

It is possible to achieve continual improvement with the aid of quality management by involving all members of staff and optimizing company procedures across all departments. Fulfilling customer requirements is central to all we do. An integrated management system for quality, environment and occupational health and safety according to EcoStep.

Environment management

As a manufacturer of environmentally friendly products based on the raw materials glass and metal Lahnau Akustik GmbH is passionately committed to protecting the environment. We wish to contribute towards balancing economy and ecology with the aim of achieving a sustainable development taking into consideration the needs of people and nature.

The ecological benefits of acoustic panels made of recycled glass:

- 100% recycled glass

- Sustainable

- Conserve natural resources

- Winner of many ecological awards

- Optimize your LEED rating

- Healthy home environment “built-in”

- Reduce CO2

- Optimize heat insulation

With you in mind, we have introduced:

An integrated management system for quality, environment and occupational health and safety. An expert assessment documented in a report verifies that the management system fulfils requirements and, as a consequence, the core stipulations of the following standards:

ISO 9001:2000

ISO 14001:2004

ILO guidelines on occupational safety and health (2001)