Seamlessly attractive, pleasantly air-conditioned, infinitely flexible

Based on the existing seamless ceiling system MIKROPOR® G FWA, the seamless acoustic ceiling MIKROPOR® G FWA Cool has been developed as a highlight of air-conditioning technology.

MIKROPOR® G FWA Cool offers the best possible combination of excellent room acoustics, air-conditioning aspects and, not least of all, aesthetic style.

Base panel:

Expanded recycled glass granulate, bound with inorganic binder

Glass-fabric reinforcement and acoustic fleece coating on both sides

Surface / visible side:

Primer and white FWA plaster applied on site using proven spray method guarantee retention of acoustic properties. If desired, in special colour as per sample.

Care / refurbishing:

It is possible to clean localized soiling using a damp synthetic sponge or brush.

Clean with a vacuum cleaner and brush. Refurbishable by spraying with Wilhelmi acoustic paint (WAF-R), without any loss of sound absorption properties.

Rear:

Acoustic membrane as on visible side

Edge configurations: Untreated cut edge

Panel thickness:

Approx. 18 mm

Format:

2500 x 1250 mm or in the custom format 1250 x 1250 mm

Weight per unit area: Approx. 7.5 kg/m2

Humidity:

Permanent high levels of humidity (> 70%) affect the dimensional stability of the panels.

Sound absorption level:

See measuring curve in the chapter Acoustic test certificates

Building material class:

A2 (s1, d0) (non-flammable)

General information:

It is only possible to fulfil the expectations and demands placed on the function of the high-quality, seamless acoustic ceiling MIKROPOR® G FWA if assembly and coating work are carried out in accordance with the factory specifications determined by Lahnau Akustik GmbH.

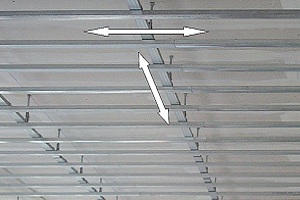

Ensure it is possible to move the entire substructure (narrow grid / support profiles) in lengthwise and crosswise directions. Request the current manufacturer and processing guidelines before commencing installation work.

SEAMLESSLY ATTRACTIVE – PLEASANTLY AIR-CONDITIONED – INFINITELY FLEXIBLE

Well-designed rooms inspire the people that live in them. Complicated interactions arise between the design of the room, the physical experience and the performance of the people working in them.

To promote the well-being of the people in their built-up environment progressive architecture has always made these associations clear and put them to specific use.

The ceiling is the least disturbed surface of a room, which is why Lahnau Akustik GmbH developed a ceiling system that is not restricted to the use of certain building grids or other functional elements on the ceiling.

Based on the existing seamless ceiling system MIKROPOR® G FWA, the seamless acoustic ceiling MIKROPOR® G FWA Cool has been developed as a highlight of air-conditioning technology.

The product is able to serve as an alternative to metal cooling ceilings; at the same time it avoids invasive operating noises and circulating air turbulence. As a consequence, it creates a particularly pleasant room climate.

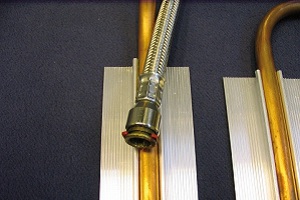

Additives are used to increase the relatively low thermal conductivity of the composite expanded glass granulate panels, without changing the essential acoustic characteristics of the expanded glass granulate.

Overheated air in a room rises and is efficiently cooled via the acoustic cooling ceiling. The result is a comfortable ambient temperature.

The system avoids draughts that occupants think is unpleasant. MIKROPOR® G FWA Cool offers the best possible combination of excellent room acoustics, air-conditioning aspects and, not least of all, aesthetic style.

WHY MIKROPOR® G FWA COOL?

Atmosphere of well-being

- Constant pleasant atmosphere

- No unpleasant draughts

- Comfort

- Avoids invasive operating noises and circulating air turbulence

Infinitely flexible

- High level of architectural design freedom

- Contiguous surfaces up to 100 m2 without expansion joints

- Coating with Alvaro® finishing plaster (0.3-0.5 mm)

Acoustically effective

- Acoustic panels MIKROPOR® G FWA Cool retain their acoustic properties when installed in combination with a cooling system

Easy to use

- Installing the substructure

- Laying the cooling meanders

- Testing the pressure and for leaks

- Installing the panels

- Filling and sanding down

- Coating

Further advantages

- Acoustic panels separate from cooling system

- High light reflectance

- Refurbishable

- High thermal conductivity

- Building material class A2 (non-combustible)

- Environmentally friendly and harmless to health

- Ecological building material

- Panel format 2500 mm x 1250 mm

We develop effective acoustic building materials in close cooperation with scientists, clients, architects and contractors. Utilizing these high-quality materials facilitates optimum speech intelligibility in our built-up environment.

At the same time, the design options available with regard to material, surface, colour and shape are so varied that it is possible to efficiently combine the demands placed on man and an eco-friendly architecture with one another on the basis of the latest scientific findings.

A variety of acoustics tests are available to download from the Download archive.

General Information:

The specifications are state-of-the-art; nevertheless, it remains the responsibility of the person/persons carrying out the work to maintain quality and workmanship consistent with best practice.

Construction and variants subject to technical modifications due to continual further development. All rights reserved. This version supersedes all previous versions.