Seamless acoustic system

AKUSTAPLAN® 1.0 mm grain size

ALVARO® 0.5-0.7 mm grain size

ALVARO Finisher® 0.3-0.5 mm

LAHNAU FINISHING PLASTER® 0.1-0.3 mm grain size

The Mikropor G FWA ceiling system fulfils the highest demands with regard to visible appearance. The non-directional surface ensures the ceiling system is ideally suitable for all areas of applications and property solutions. The high level of light reflectance of the surface and the ease with which all of the fixtures built into the ceiling are integrated offer you undreamt of design options.

Base panel:

Expanded recycled glass granulate, bound with inorganic binder, glass-fabric reinforcement and acoustic fleece coating on both sides

Surface / visible side:

Primer and white FWA plaster applied on site using proven spray method guarantee retention of acoustic properties. If desired, in special colour as per sample.

Care / refurbishing:

It is possible to clean localized soiling using a damp synthetic sponge or brush. Clean with a vacuum cleaner and brush. Refurbishable by spraying with Wilhelmi acoustic paint (WAF-R), without any loss of sound absorption properties.

Rear:

Acoustic membrane as on visible side

Edge configurations: Untreated cut edge

Panel thickness:

Approx. 18 mm

Format:

2500 x 1250 mm or in the custom format 1250 x 1250 mm

Weight per unit area: Approx. 7.5 kg/m2

Humidity:

Permanent high levels of humidity (> 70%) affect the dimensional stability

of the panels.

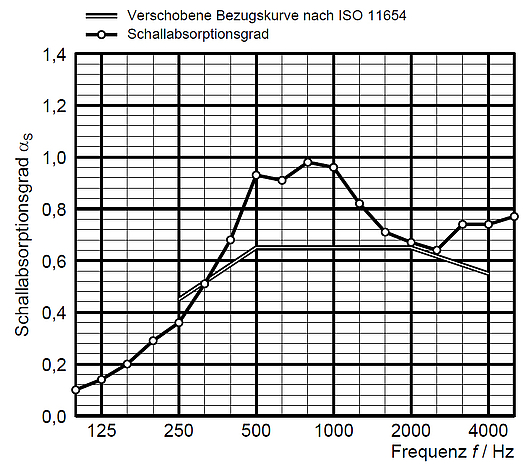

Sound absorption level:

See measuring curve in the chapter Acoustic test certificates

Building material class:

A2 (s1, d0) (non-flammable)

General information:

It is only possible to fulfil the expectations and demands placed on the function of the high-quality, seamless acoustic ceiling MIKROPOR® G FWA if assembly and coating work are carried out in accordance with the factory specifications determined by Lahnau Akustik GmbH.

Ensure it is possible to move the entire substructure (narrow grid / support profile) in lengthwise and crosswise directions. Request the current manufacturer and processing guidelines before commencing installation work.

We develop effective acoustic building materials in close cooperation with scientists, clients, architects and contractors. Utilizing these high-quality materials facilitates optimum speech intelligibility in our built-up environment.

At the same time, the design options available with regard to material, surface, colour and shape are so varied that it is possible to efficiently combine the demands placed on man and an eco-friendly architecture with one another on the basis of the latest scientific findings.

A variety of acoustics tests are available to download from the Download archive.

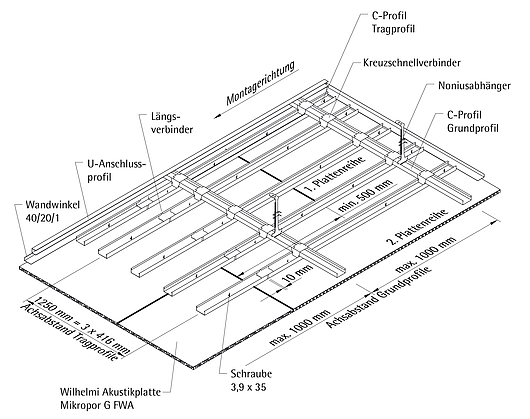

Installing the substructure

The temperature during processing must not fall below 12 °C. The relative humidity should be at least 30%, however it should not exceed 70%!

Use components from a single system for the substructure! Approved substructures are: Suckow + Fischer or Lahnau Akustik.

Ensure it is possible to move the entire substructure (narrow grid / support profile) in lengthwise and crosswise directions. Do not use angle anchors!

Avoid different pressure ratios arising between the ceiling voids and usable space; due to the physical properties of the ceiling system this can lead to the surface becoming soiled.

Appropriate measures will be required if a partial vacuum is created in the ceiling or wall voids (e.g., due to a failure to exhaust stale air) (refer to information on page 7). Consult the manufacturer before installing.

First determine the direction of installation according to the incidence of light before commencing work. Arrangement of longitudinal joints of panels (narrow grid / support profile) taking into consideration the incidence of light.

The complete documentation on installing and processing seamless Wilhelmi acoustic ceilings Mikropor® G FWA area available for download in the Downloadarchiv.

1. Cleaning

- Before cleaning with a damp cloth, carefully remove surface dust with a brush or vacuum cleaner.

- It is possible to remove localized soiling such as fingerprints or trails of soiling close to air outlets using a firm, damp sponge together with a commercially available household cleaner or Moisture-Clean (available as a powder from Lahnau Akustik) in the respective recommended concentrations.

- Then carefully wash down the cleaned surface with clean, clear water and dab dry with an absorbent cloth or paper (kitchen roll).

- We recommended you test clean an inconspicuous area each time before cleaning.

Professional refurbishment must be carried out using Wilhelmi acoustic paint WAF-R 86 (special colours WAF-R 87).

- Quantity used during refurbishment: 400-700 g/m² depending on the degree of soiling

- Ensure the room temperature does not fall below 12 °C when applying the coating; the relative humidity should not exceed 70%.

- Once applied immediately ensure the rooms are ventilated and dehumidified.

2.1 Refurbishment

If the acoustic ceiling has become heavily soiled after many years of normal use and can no longer be cleaned properly, it is possible to restore it to a condition virtually as good as new by applying a refurbishment spray.

When applied professionally in accordance with the manufacturer’s instructions the acoustic absorbency of the wall or ceiling surface is not impaired. The refurbishment can be repeated several times, if required.

Under no circumstances should emulsion paints be applied to the surfaces using a brush or roller, otherwise the sound absorbing properties will be lost.

It is only possible to guarantee the acoustic characteristics will be retained by engaging a professional company that uses the appropriate coating machinery to professionally apply the refurbishment spray, e.g.,

Strobl Beschichtungstechnik GmbH

Hermann-Volz-Straße 50

D-88400 Biberach/Riß

Tel. +49 7351/4400-0

Fax +49 7351/4400-60

Quality management

It is possible to achieve continual improvement with the aid of quality management by involving all members of staff and optimizing company procedures across all departments. Fulfilling customer requirements is central to all we do. An integrated management system for quality, environment and occupational health and safety according to EcoStep.

Environment management

As a manufacturer of environmentally friendly products based on the raw materials glass and metal Lahnau Akustik GmbH is passionately committed to protecting the environment. We wish to contribute towards balancing economy and ecology with the aim of achieving a sustainable development taking into consideration the needs of people and nature.

The ecological benefits of acoustic panels made of recycled glass:

- 100% recycled glass

- Sustainable

- Conserve natural resources

- Winner of many ecological awards

- Optimize your LEED rating

- Healthy home environment “built-in”

- Reduce CO2

- Optimize heat insulation

With you in mind, we have introduced:

An integrated management system for quality, environment and occupational health and safety. An expert assessment documented in a report verifies that the management system fulfils

requirements and, as a consequence, the core stipulations of the following standards:

ISO 9001:2000

ISO 14001:2004

ILO guidelines on occupational safety and health (2001)