MIKROPOR® M Acoustic Ceiling System with integrated cooling technology

In addition to their fire protection and acoustics properties it is possible to add a decisive function to cooling ceilings from Lahnau Akustik by integrating air-conditioning systems. Integrated cooling technology turns them into multi-functional building elements that fulfil the highest demands across all of their working ranges.

The synthesis of aesthetics and function is central to Lahnau Akustik: It forms the basis of the systems that have made the name Lahnau Akustik GmbH and our predecessor company Wilhelmi Werke known worldwide in the field of interior finishing.

In addition to their fire protection and acoustics properties it is possible to add a decisive function to cooling ceilings from Lahnau Akustik by integrating air-conditioning systems.

Integrated cooling technology turns them into multi-functional building elements that fulfil the highest demands across all of their working ranges.

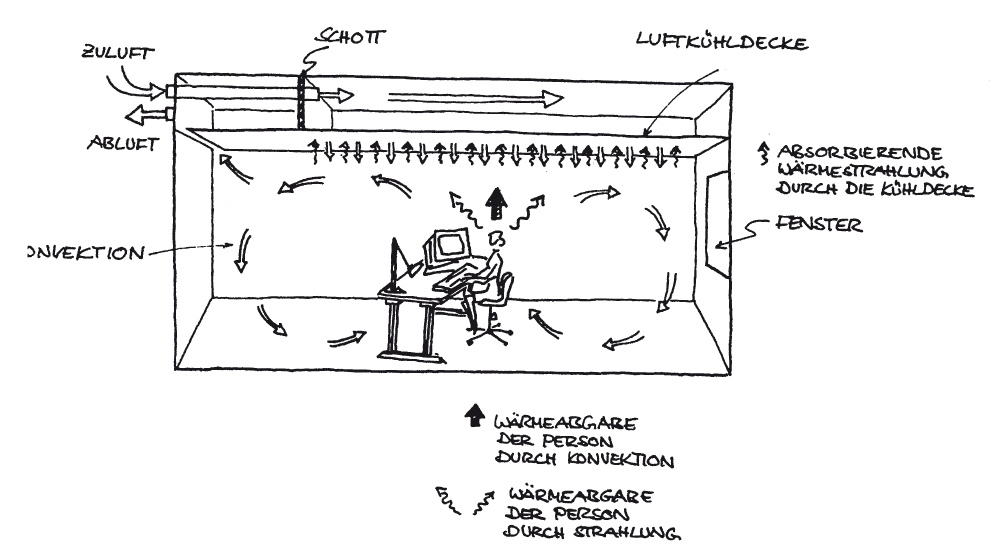

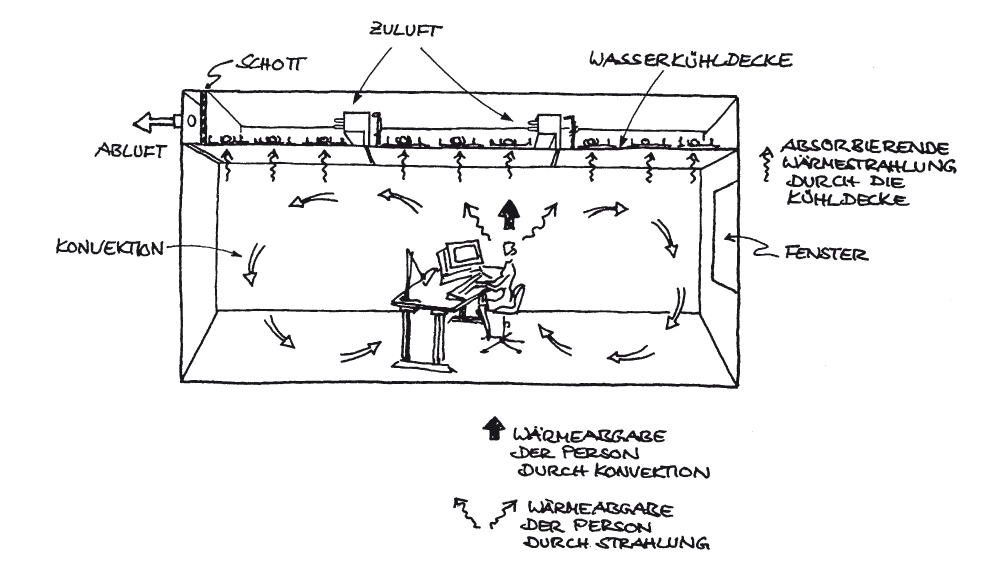

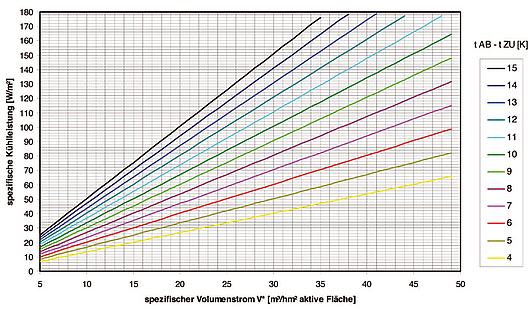

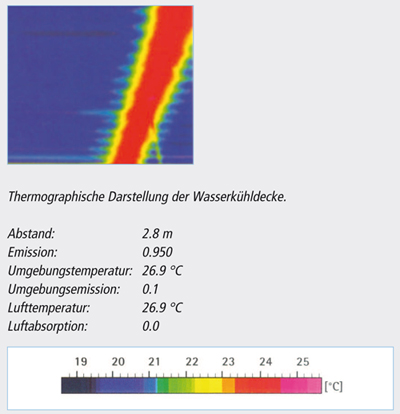

The heat transfer medium used is either air or water. In both cases, the climate in the room is regulated according to the principle of “gentle cooling”. In addition to the best-possible comfort, both cooling ceiling versions are distinguished not least by their remarkably low energy consumption.

Our advantages:

- High light reflectance

- Refurbishable

- Large format

- High thermal conductivity

- System independent

- Invisible, silent

- Energy saving

- Low installation height

- Up to 100 W/m2 active cooling capacity

- Intuitive, individual temperature control

- Flexible – changeable room configuration

- Practically maintenance-free

The better concept with regard to thermal comfort

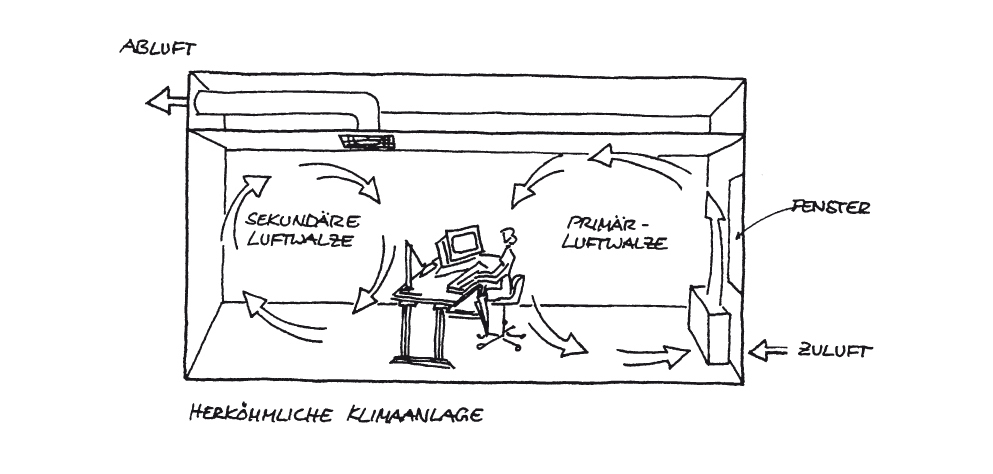

Maintaining at a constant room temperature is a precondition for a sense of well-being. Conventional air-conditioning systems are unable to achieve this objective without side effects. On the one hand these include the typical, unmistakeable background noise and on the other hand the likelihood of draughts due to the higher velocity of the air as it flows through the room as well as numerous sizeable air inlets and outlets.

But, it does not have to be like that: invisible, silent and draught-free. It is worth bearing in mind that cooling ceilings from Lahnau Akustik not only cool very efficiently and heat selected areas, they are also save energy.

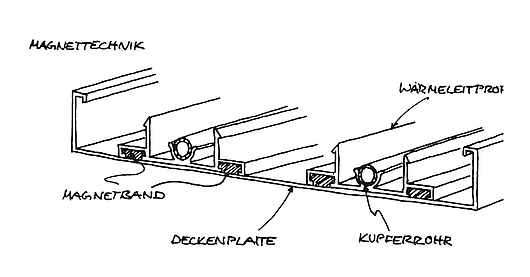

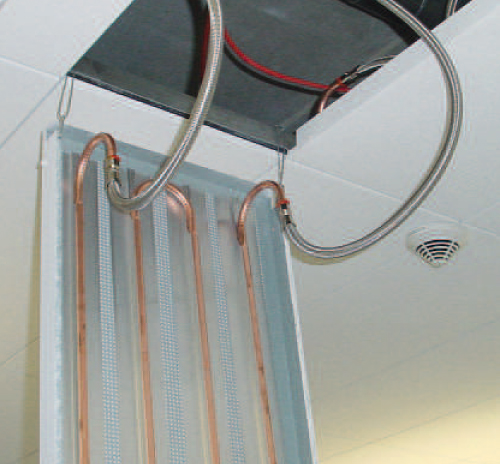

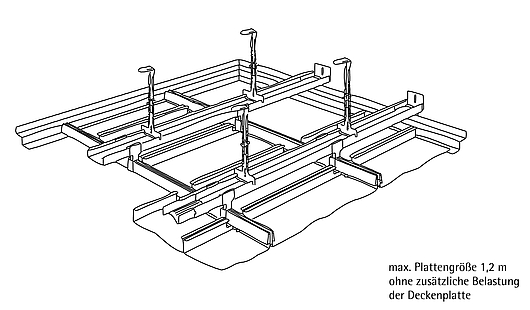

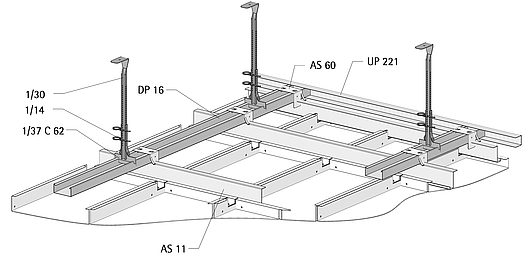

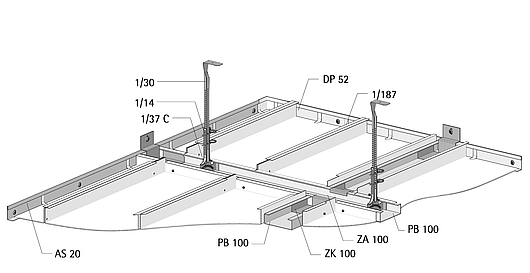

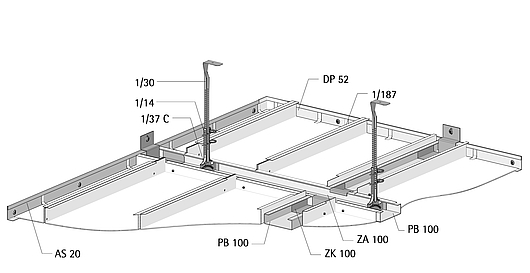

Installation of the water-cooled Wilhelmi ceiling system:

- Mikropor® M acoustic panels, coated on the visible side with Wilhelmi acoustic paint (WAF)

- Cooling meander assembly made of copper tubing

- Heat dissipation channels made of extruded aluminium with integrated magnetic strips

- Substructure made of galvanized sheet steel.

Test report

Test report No.: FTZ_2008_KF2085 On determining the cooling performance of a room cooling service to DIN EN 14240

Coffered ceiling M. C. I. Metalldecken GmbH & Lahnau Akustik GmbH, “MCI/MIKROPOR®M - MCI - 100/60-12”

is available on request or in our Download archive.

THE AIR COOLING CEILING ACOUSTAIR®

gentle cooling – without air inlets and cooling registers

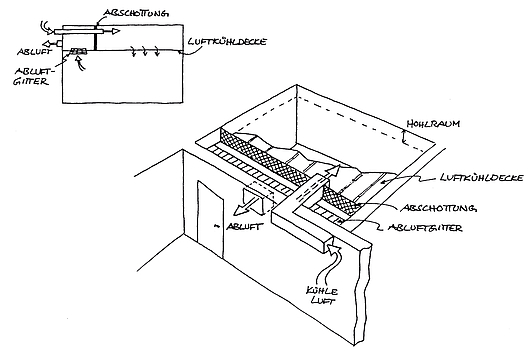

The principle behind the air cooling ceiling AcoustAir® is unique and surprisingly simple. It is based on air permeability of the microporous coating across the whole area of the Mikropor® M acoustic panels:

1. The joints of the suspended ceiling are sealed to allow a slight overpressure to build up in the ceiling void.

2. Cooled air is fed into the ceiling void to build up the appropriate level of overpressure.

3. The conditioned air flows silently and without condensation through the microporous surface fleece of the Mikropor® M acoustic panel and into the room. At the same time it also cools the metal acoustic ceiling; in doing so it supports the dissipation of heat by means of radiation interchange.

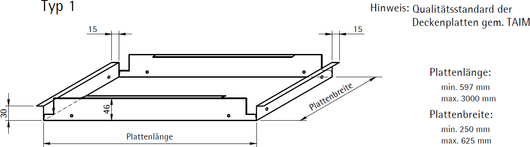

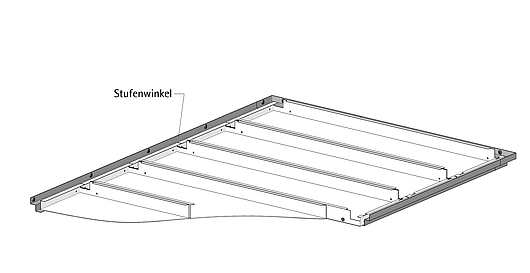

The air cooling ceiling AcoustAir® is based on a connection between a special substructure and special type 3LK metal panels, which can be effectively sealed around the edges (see drawing).

The conditioned air enters the ceiling void or rather the individual ceiling chambers via ventilation ductwork. From here it flows across the whole of the active surface and into the room at a minimum outlet velocity where it removes the stale air across a wide area in a process perceived by the occupants as extremely pleasant.

This principle creates all of the conditions to achieve a high level of thermal comfort, offers the interior room designer maximum freedom to design the room – and the ceiling – and also cuts a good figure when the investment costs are presented.

Air cooling ceiling - how it works

The sealing system ensures air leaves the hanging metal ceiling across a wide microporous surface area.

| Luftwechsel | Zuluft | 1 cm vor Durchdringen der Luft | Plattenrückseite | Plattenvorderseite | Raumtemperatur |

| 3-fach | 11,0 °C | 19,4 °C | 21,6 °C | 22,5 °C | 26,0 °C |

| 4-fach | 11,0 °C | 19,0 °C | 21,1 °C | 22,1 °C | 25,9 °C |

| 8-fach | 11,0 °C | 16,3 °C | 18,5 °C | 20,0 °C | 26,0 °C |

Colours & surfaces

Products from Lahnau Akustik offer numerous design options.

We offer a huge choice of special colours and surfaces. We are happy to offer advice.

Further information on colours & surfaces is available with our product MIKROPOR® M.

Acoustics

We develop effective acoustic building materials in close cooperation with scientists, clients, architects and contractors. Utilizing these high-quality materials facilitates optimum speech intelligibility in our built-up environment. The corresponding acoustics test certificates are available in the Downloadarchiv and with our product under MIKROPOR® M

Cleaning & refurbishing

One of the main advantages of our acoustic panels is that it is possible to clean and wash down their surfaces.

It is possible to clean localized soiling on surfaces using water and normal washing up liquid.

If the ceilings have turned yellow or become dirty over the years, which is actually quite normal for all acoustic ceilings, we are able to refurbish them while they are still installed. Further details available with our product MIKROPOR® M.

Ecology

It is possible to achieve continual improvement with the aid of quality management by involving all members of staff and optimizing company procedures across all departments. Fulfilling customer requirements is central to all we do. Integrated management system for quality, environment and occupational health and safety to EcoStep. Further details available with our product MIKROPOR® M.